Document Type : Original Article

Authors

- Ahmed H. Hussein 1

- Walla Mohamad 1

- Ahmed D. Abid Muslim 2

- Ali I. Salman 1

- Mohannad F. Abdu Al-Hussein 2

- Ameer M. Muhammad 2

- Zharaa A. Hassan 2

1 Department of Pharmaceutics, College of Pharmacy, University of Al Kafeel, Najaf, Iraq

2 Najaf Health Directorate, Ministry of Health Najaf, Iraq

Abstract

Emulsions could be defined as heterogeneous system thermo-dynamically unstable of a two-phase system consisting of at least two immiscible liquids. A third component, the emulsifying agent, is necessary to stabilize the emulsion. Etodolac is used to relieve pain, swelling, and joint stiffness from arthritis. The local administration of the drug topically will avoid the systemic side effects besides some advantages making it a superior dosage form. The present study aims to formulate and evaluate nanoemulsion composed of different oils and surfactant system systems and find the best microemulsion formula in terms of particle size and stability. The present study includes making different emulsion formulas and implementing etodolac into them. The formulas were made by wet gum using DW, oils (almond and eucalyptus), and surfactants (tweens, span, and triton X). Experiments were then done on the formulas to choose successful ones to put etodolac into. One of the successful formulas had etodolac implemented into them and further experiment were done after. Finally, etodolac was tested in-vivo in the form of cream to see its efficacy by a pharmacologist.

Results revealed that all prepared formulas succeeded in giving emulsion but with variable degree of properties and stability. Their pH are acidic with no sensitization to skin. Selected formula Fe2 contains eucalyptus oil and a mixture of tween40 and triton x is the best formula in terms of stability, reliability, and globular size. Upon addition of etodolac drug formula still stable and globular size is small and uniform under laser diffraction analyzer. Eucalyptus and almond oils can give stable emulsion. Oil in water emulsion type is predominant in all prepared formulas. A stable and promising formula was obtained with no sensitization was seen, and this formula is ready to be applied to human skin after some more tests to be marketed as microemulsion formula for the analgesic drug etodolac.

Graphical Abstract

Keywords

Main Subjects

Introduction

Transdermal administration of medication is rapidly growing approach worldwide. This approach can deliver several important essential active pharmaceutical ingredients (API) passing skin layers and reaching the muscles or blood stream. Drugs to pass transdermally must have balanced hydrophilic and lipophilic properties. Since neither extremely hydrophilic drug nor extremely lipophilic drug can pass skin barriers [1]. The emulsion system could provide this property of balanced properties composed of oil phase dispersed in the water phase (as in the case of O/W emulsion). Unfortunately, emulsions are thermodynamically unstable systems and need to be stabilized by the addition of emulsifying agent [2]. Emulsion stabilization is not an easy process and needs extensive study and tastings for emulsion components ratios and type and concentration of emulsifying agent [3].

On the other hand, emulsion droplets could be reduced in size from micrometers o nanometers to reach a very small size to produce nano-emulsions, which are homogeneous, transparent systems with a minimal droplet size than coarse emulsions. It is thermodynamically more stable than coarse emulsions [4].

Etodolac (ET) is one of the NSAID with analgesic and antipyretic properties. It is used to treat osteoarthritis rheumatoid arthritis and control acute pain. Etodolac is 5 – 50 times more selective for COX-2 than COX-1, thus producing fewer gastrointestinal side effects. It has a water solubility of 16 mg/L. Molecular Weight equal to 287.35, log P= 2.8. Etodolac is insoluble in water and soluble in ethanol by about 20 mg/ml [5]. This work aims to formulate, stabilize, and evaluate etodolac nanoemulsion formulas composed of different oils and surfactant systems to reacha stable formula candidate to be a prototype for transdermal permeation.

Material and Methods

Almond oil, Ethanol, Etodolac powder, Eucalyptus oil were purchased from Himedia - India. Triton x was purchased from Sigma - Germany. Tween 40 and Tween 80 were purchased from Alpha chemika- India. All other materials and instruments used in the present study are within an analytical grade.

Method of Preparation of Nanoemulsion

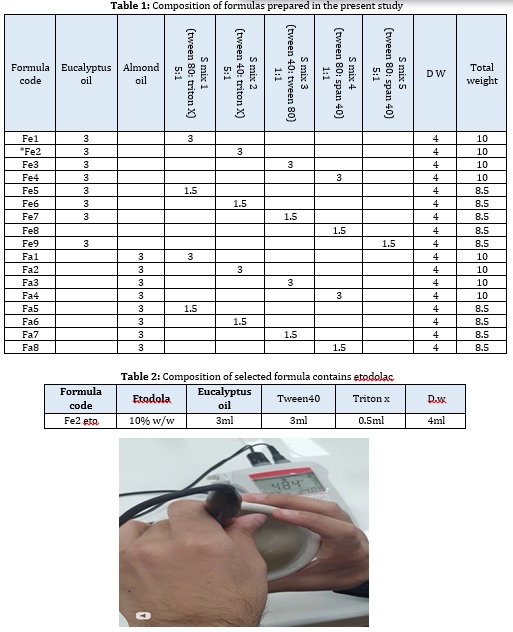

To obtain the proper formula with the required properties in terms of stability and miscibility, several formulas were prepared using different types of oils as almond and eucalyptus oils, and different types of surfactant and co-surfactant are utilized as illustrated in Table 1.

English (Wet Gum) Method was chosen to prepare formulas. After measuring the appropriate amount of oil, Smix, and DW, add 3 mL/1.5 mL of Smix then 4 mL of DW in a mortar. Afterward, triturate by pestle for 5 min then add 3 ml of eucalyptus or almond oil gradually until hearing clicking sound and put in a test tube. This method was applied for all formulas. Prepared formulas were stored in the fridge for further investigation [6].

In addition to adding the drug etodolac (10% w/w), the formula containing etodolac (Fe10) was prepared using the same compositions of eucalyptus formulas (Fe 2). All prepared formulas were sonicated in a bath sonicator and were done for 5 min to prepare the microemulsion [7].

Characterization of prepared formulas

Methods of Characterization

Several tests were performed to evaluate the prepared formulas in terms of gross appearance, stability, globular size, and viscosity. Products in the present study were evaluated by vision if separated into two layers or not, and we also depended on microscopic examination. Product gross quality was classified into excellent, good, fair, poor, wrong categories.

Determination of pH

pH of topical formulas must be near neutral to avoid any skin irritation [1]. pH meter was utilized to detect the pH of the selected formula with drug and without drugs. The pH without the drug for the selected formula was 5.6, while the one with the drug is 4.6. This indicates that the presence of etodolac decreased the pH, which may mean that the drug has acidic nature (Figure 1).

Figure 1: pH testing of Fe2 etodolac emulsion

Determination of Globule Size under Optical Microscope

Microscopic examination was done at zero time for the selected formula with drug and without drug under highest power (X100). The result was a small particle size for the selected formula with drugs and without drugs. Other formulas were tested and found that their particle size was between intermediate and large.

Gross Examination

Appearance of Emulsion

The successful emulsions prepared had off white color and homogenous appearance. Grossly, the emulsions prepared were with intermediate viscosity. The non-selected formulas also had similar appearances but suffered from low viscosity and presence of transparent part aside from the white part, indicating separation [8]. In addition, all prepared formulas were evaluated for the presence or absence of M. O. growth (Figure 2).

Figure 2: Primary emulsion of Fe2 (successful formula) gross appearance

Stress stability testing (Freezing thawing test)

Breaking of emulsions is one of the significant problems associated with emulsions. For that reason, a particular test must be performed to ensure its stability among these tests is stress testing by multiple freezing and thawing and if the prepared emulsion withstand this test so one can say that he passes some way to prove formulas stability. Each formula was putted in a covered test tube and thenstored in a freezer for 12 h and then let be melted for another 12 h (this is a single circle) and repeated this cycle 3 times and recorded results. Freezing and thawing were done for all the formulas (Figure 3).

Figure 3: A: Formulas before freezing and thawing, B: Formulas after freezing and thawing

Centrifugation Test

A centrifugation test was performed for the selected formula with drug and without drugs to evaluate its stability [9,10]. The procedure included putting the formulas in Eppendorf tubes and then centrifuging them for 20 min at 5000 rpm.

Determination of emulsion type dye test

Water-soluble dye distribution gives an idea about the type of emulsion if it distributes in the external phase so that the emulsion will be O/W and vice versa [11]. The dye test was done by adding methylene blue drops to the emulsion formulas (on a small glass dish). All the formulas showed that they are O/W type, including the selected formula. Figure 2 shows the test.

Dilution Test

Put a small amount of formula in a beaker and add enough DW. After that, mix and observe the mixture, and if separation to two layers happens, then this means the emulsion is W/O, while if the mixture did not separate into two layers, then this means that the emulsion is O/W [12].

Determination of Particle Size and Particle Size Distribution

The laser diffraction technique, was utilized on the selected formula with the drug to determine the particle size and particle size range. A small amount of the sample after treatment was implemented into the instrument cell, and afterward, results were obtained and recorded.

Sensitivity Test

One of the basic properties of any topical dosage form is that it must not sensitize the skin. As all emulsion formulas contain SAA, which may cause harmful effects to the skin. For that reason, a researcher must checkthe degree of sensitizing to the skin [1]. Thus, the sensitivity test was done on 15 volunteers using the selected formula Fe2 with drug. This test was performed by applying two drops of the formula on the hand skin of the volunteer and seeing if any sensation reaction occurs. The test was considered as negative when [4].

Long term stability test

Selected formulas were prepared and stored in a dark place at room temperature and investigated grossly every month for six consecutive months.

Statistical analysis

All formulas and tests were performed in triplicate, and all data were expressed as a mean± standard deviation. Using Microsoft Excel, significant differences in the mean values were evaluated by unpaired test or one-way analysis of variance (ANOVA). A p-value of less than 0.05 was considered significant, while pP-value of more than 0.05 was considered non-significant.

Result and Discussions

Results revealed that all prepared formulas succeeded in formulating emulsion but with variable degrees of properties and stability. The successful formulas, that contain eucalyptus oil ando Triton X as emulsifier andotherr ingredients (Table 2) were selected to add etodolac to it in the same proportions and for further investigation and characterization.

Gross Investigation

Products in the present study were evaluated by vision if separated into two layers or not, and we also depended on microscopic examination (size of particle while the small size of a particle is preferable) in the evaluation of the product quality if it was very good, good, fair, poor, bad. All prepared formulas were homogenous in shape and odors [12], as shown in Table 3.

Determination of pH

Three selected formulas ere tested in their pH value and found to be acidic in nature and around 4-5. This could be attributed to a lot of free fatty acid in oils utilized (eucalyptus oil). pH value without the drug for the selected formula was 5.6, while the one with the drug is 4.6. This indicates that the presence of etodolac decreased the pH, which may mean that the drug has acidic nature, as seen in Table 3.

Determination of emulsion type

All prepared formulas were found to be O/W, and these results are based on the results obtained from both dye and dilution tests, as demonstrated in Table 3. These results could be attributed to the type of emulsifying agent used, which favour to produce O/W rather than another type of emulsions [12].

Centrifugation Test

A centrifugation test was performed for the selected formula with drug and without drugs to evaluate its stability. A centrifugation test was performed for the selected formula with drug and without drugs to evaluate its stability [9,10]. The procedure included putting the formulas in Eppendorf tubes and then centrifuging them for 20 min at 5000 rpm. The selected formula without drug after centrifugation remained stable without separation into two layers. The selected formula was found to withstand centrifugation, indicating its stability and reliability.

Determination of Emulsion Absorption and Sensitivity

One of the required properties for any topical dosage form is that it must not be harmful or sensitizer to the skin. Thus, the sensitivity test was done on 15 volunteers using the selected formula with a drug. The result was that only one of them suffered from a burning sensation after a few drops of application [4]. Table 3 shows variable effects upon formula application on volunteer skin ranging from cooling effect as in Fe2, 6 to no effect in Fe5 and heating effect as in Fe7. On the other hand almost formulas were absorbed rapidly, leaving no traces on the skin except Fa1 and Fa3.

Microbial Contamination upon Storage

Microbial contamination was seen in Fe1 and Fa4, while other formulas show no contamination and growth of M.O., as seen Table 3.

Appearance of emulsion:

The successful emulsions prepared had white color and homogenous appearance. Grossly, the emulsions prepared were with suitable viscosity. The failing formulas also had similar appearances but suffered from low viscosity and transparent part aside from the white part, indicating separation [8].

Freezing Thawing Test

Freezing and thawing were done for all the formulas. Nearly all the formulas spoiled under the effect of variable temperature except Fe 2, 3, and 4 and Fa2 and 3 in addition to Fe2 containing etodolac. The successful formula (Fe 2) held with nearly no separation in it. Some of the formulas managed to hold while others did not last seconds and separated hastily. These results may be due to the type of emulsification system. On the other hand, all prepared formulas have survived the cooling –heating test, which means that the surfactant system utilized was able to keep these formulas stable in moderate temperatures (Figure 3).

Figure 3: Gross appearance of some prepared formulas

Determination of particle size and particle size distribution

Optical microscope and Laser diffraction technique was used [13] on the selected formula with the drug to determine the particle size and particle size range [14]. Selected formulas were tested under a light microscope at zero time under (X100) strength. The result was a small particle size for the selected formula with drugs. Only scattered globules were seen under a light microscope, while the bulk of globules were invisible. These results will be more confident as the results from laser diffraction were interpreted since they were found to be in the nano range (about 50 -100 nanometer), as seen in Figure 4. In addition, the Globular size of Fa2 was found to be around 4400-5000 nanometer with narrow size distribution indicating uniform in size and hence a more stable emulsion [14], as seen in Figures 5and 6.

Figure 4: A- Fa2 formula under microscopic examination B -Formula Fe2 under microscopic examination

Long term stability testing

After six months of storing the prepared formula in a dark closet at room temperature [15], the formula wasstable without gross change in initial properties besides no gross change in globular size, as seen in Figure 7.

Figure 7: Selected formula Fe2 containing etodolac after six months of stability testing

Conclusions

- Eucalyptus and almond oils both can give a stable emulsion

- Tween40 with tritonX is a good emulsification system

- Oil in water emulsion type is predominant in all prepared formulas

- Stress tests are crucial in deciding emulsion stability

- Eucalyptus oil gives particle size is small and with a narrow size distribution

- No sensitization was seen, and the formula is ready to be applied to human skin

Recommendation

- Perform long term stability test for the selected formula

- Extensive study in vivo to prove drug activity

- The formula obtained could be used for the treatment of muscle pain and arthritis

Funding

This research did not receive any specific grant from fundig agencies in the public, commercial, or not-for-profit sectors.

Authors' contributions

All authors contributed toward data analysis, drafting and revising the paper and agreed to responsible for all the aspects of this work.

Conflict of Interest

The authors have no conflicts of interest relevant to this article.

ORCID:

Ahmed H. Hussein

https://www.orcid.org/0000-0002-8750-9533

HOW TO CITE THIS ARTICLE

Ahmed H. Hussein, Walla Mohamad, Ahmed D. Abid Muslim, Ali I. Salman, Mohannad F. Abdu Al-Hussein, Ameer M. Muhammad, Zharaa A. Hassan. Preparation and Evaluation of Etodolac Nanoemulsion, J. Med. Chem. Sci., 2022, 5(5) 760-768

- Benson H.A.E., Drug Deliv., 2005, 2:23 [Crossref] [Google Scholar] [Publisher]

- Sacanna S., Kegel W.K., Philipse A.P., Rev. Lett., 2007, 98:158301 [Crossref] [Google Scholar] [Publisher]

- Abbas H.K., Bader Q.A., Hussein A.H., Shaheed D.Q., J. Pharm. Res., 2020, 12:422 [Crossref] [Google Scholar] [Publisher]

- Rivera-Rangel R.D., González-Muñoz M.P., Avila-Rodriguez M., Razo-Lazcano T.A., Solans C., Colloids Surf. A Physicochem. Eng. Asp., 2018, 536:60 [Crossref] [Google Scholar] [Publisher]

- Rathi P.B., Deshpande K.V., Solution Chem., 2014, 43:1886 [Crossref] [Google Scholar] [Publisher]

- Comunian T.A., Ravanfar R., Alcaine S.D., Abbaspourrad A., Food Res. Int., 2018, 106:945 [Crossref] [Google Scholar] [Publisher]

- Higuchi W.I., Pharm. Sci., 1962, 51:802 [Crossref] [Google Scholar] [Publisher]

- Chillistone S., Hardman J.G., Intensive Care Med., 2017, 18:335 [Crossref] [Google Scholar] [Publisher]

- Restu W.K., Sampora Y., Meliana Y., Haryono A., Procedia Chem., 2015, 16:171 [Crossref] [Google Scholar] [Publisher]

- Li Z., Geng H., Wang X., Jing B., Liu Y., Tan Y., Eng. J., 2018, 354:1110 [Crossref] [Google Scholar] [Publisher]

- Samanta A., Ojha D., Mukherjee B., Sci., 2010, 02:494 [Crossref] [Google Scholar] [Publisher]

- Aditya N.P., Aditya S., Yang H.J., Kim H.W., Park S.O., Lee J., Ko S., Funct. Foods., 2015, 15:35 [Crossref] [Google Scholar] [Publisher]

- Chen G., Tao D., Fuel Process. Technol., 2005, 86:499 [Crossref] [Google Scholar] [Publisher]

- Grenoble Z., Trabelsi S., Colloid Interface Sci., 2018, 260:32 [Crossref] [Google Scholar] [Publisher]

- Arab D., Kantzas A., Bryant S.L., Pet. Sci. Eng., 2018, 163:217 [Crossref] [Google Scholar] [Publisher]